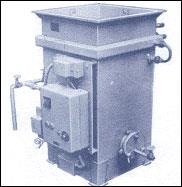

Single Stage Ultrasonic Cleaning System

Appropriate liquid is poured in the tank for removing specific contamination. Heating if desired also incorporated. The job is loaded on jigs. Fixtures, Wire, Baskets or any other convenient method and immersed in tank for prescribed time. Single stage Ultrasonic Cleaning system is useful with Neutral or Alkaline liquid. Acidic solution to be used with special arrangements.